Laser Cleaning Over Sand/Soda Blasting

for Surface Profiling

Overview:

Media Blasting and The Challenge of Working Conditions

When it comes to the actual act of media blasting, it is a straightforward process. You have a problem, a contractor has a solution and the technology to execute on that solution, but it is the right technology for the job? What often times gets overlooked by a client and/or contractor is the working environment. Media blasting solutions such as sandblasting or soda blasting are effective, but produce many negative complications that make them inefficient in certain working environments.

While sand blasting may be quick, the amount of time needed to properly clean the working location of media debris is painfully slow and often times media remains for weeks after the blasting has been completed. In many cases the sand media remains lodged in the surface creating adhesion issues for the new coating application. Outside of the clean up, secondary waste from sand and soda blasting poses significant health risks, including respiratory issues, allergic reactions, and other serious health conditions.

Media Blasting Alternative: Laser Cleaning

Outside of the environmental concerns surrounding sandblasting and soda blasting, they can also cause potential damage to structures due to their harsh cleaning methods. Their gift (speed and power) is often their downfall. Merritt Industrial employs media cleaning solutions that yield fast turn-around times while eliminating key flaws:

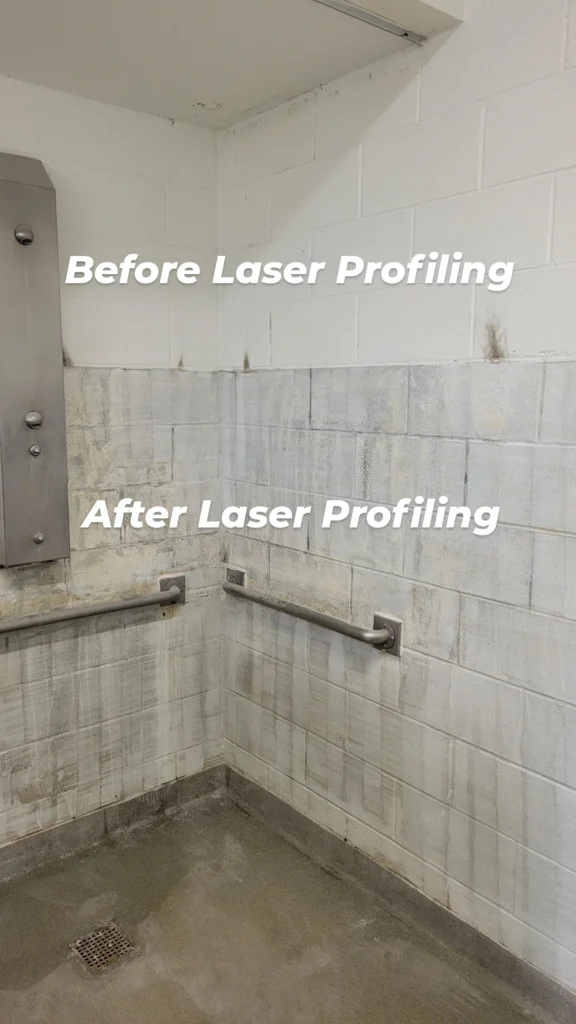

- Raw Power: SandBlasting and soda blasting are often too powerful and will remove too much material requiring additional work prior to applying a new finish. This painted surface profiling project we used our 1,000w pulse laser to quickly and effectively profile the cement block for proper epoxy bonding. Our technicians were able to achieve the correct profile on 850sqft in just six hours including setting up and cleaning the workspace once finished.

- Ventilation: Poor ventilation when media blasting will create large dust plombs that will filter to areas outside of the cleaning focus area. Given our eco-friendly laser cleaning solution, we were able to maintain a clear air workspace by utilizing air scrubbers and temporary walls resulting in virtually no air or adjacent environment contamination. Even the fire/smoke detection system was left in operation and never tripped!

- Building Materials: Certain building materials, like wood, cement block, soft metals, conduit and drywall, will easily be damaged by aggressive media blasting. Our laser cleaning services are safe on the surface an allowed our technicians to remove three layers of old epoxy sealer from the cement block without causing any damage to the block surface or motor joints.

Merritt Industrial: A Leader in Sustainable Media Blasting

Founded in 2020, Merritt Industrial has evolved to become an established leader in the field of safe and eco-friendly media blasting services. We offer professional expertise and unparalleled customer service. Our company’s commitment to excellence, innovation, and environmental sustainability make Merritt Industrial an ideal partner for any media blasting project, large or small scale.

- Extensive Experience: With years of experience in the industry, Merritt Industrial has honed its techniques and built a reputation for delivering high-quality results. Our team of skilled professionals is adept at handling a wide range of surface cleaning and remediation projects, from small residential jobs to large scale industrial sites.

- Cutting-Edge Laser Cleaning Technology: Merritt Industrial invests in technology. This ensures that our clients benefit from the most efficient and effective cleaning and remediation solutions available.

- Customized Solutions: The facts are that every project is unique with specific needs. Merritt Industrial works closely with our clients to develop tailored solutions that meet the specific needs of each project. This collaborative approach ensures optimal results and client satisfaction

- Commitment to Safety: Safety is a top priority for Merritt Industrial. Our crews are trained in the latest safety protocols and best practices, ensuring that every project is conducted safely and efficiently.

- Environmental Stewardship: At Merritt Industrial we are committed to environmental sustainability. By utilizing eco-friendly cleaning methods, we minimize the use of harmful chemicals and reduce waste, contributing to a cleaner and healthier environment.

Comprehensive Services Provided by Merritt Industrial

Merritt Industrial’s comprehensive range of services ensures that all aspects of your project are covered. These services include:

- Assessment and Inspection: The first step in any laser cleaning project is a comprehensive assessment and inspection of the estimated work and working environment. Merritt Industrial’s staff is trained to identify pain points and/or site complications so we can provide an accurate scope of work estimate. This detailed evaluation helps in planning the most effective strategy.

- Plan Development: Based on the assessment, Merritt Industrial develops a customized project plan. This plan outlines the steps our firm will be, the equipment to be used, milestones to be met and the expected timeline(s). The plan is tailored to meet the specific needs of your project, ensuring efficient and effective results.

- Project Execution: Once we have established steps 1 & 2, it’s time for work! Our skilled technicians ensure that the process is carried out safely and effectively, minimizing disruption and secondary contamination.

- Post-Cleaning Verification: After our work has been completed, Merritt Industrial conducts a thorough inspection to ensure that all agreed actions have been fulfilled.

- Future Planning: Merritt Industrial provides consultation on potential fixed cost service level agreements to help avoid future emergency cleaning needs.